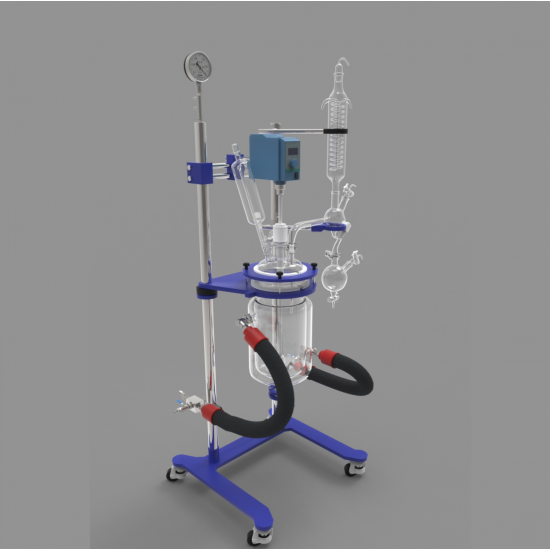

Product Details

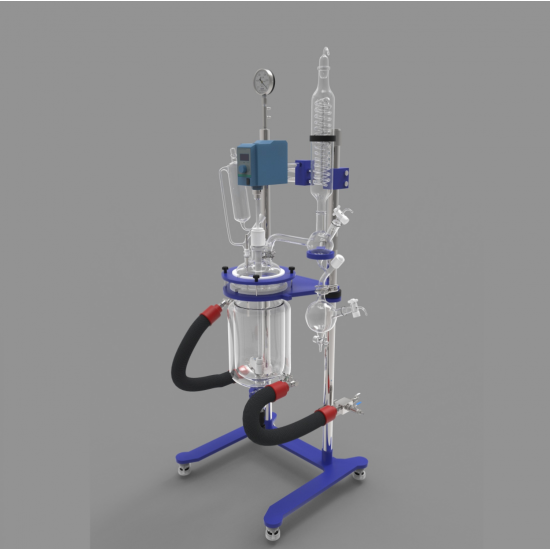

This machine has an

electric constant speed mixing system, condensation, dripping system, and the

interlayer of the kettle body needs to be externally heated or refrigerated.

While stirring the materials, circulating hot solution or cooling liquid is

injected through the interlayer to heat or cool the materials in the kettle at

a constant temperature. When the material is heated and reacted, the

evaporation efficiency can be improved under vacuum conditions (need to connect

a vacuum device), the solvent vapor will be cooled into a liquid when it passes

through the glass condensing coil (need to connect to a cooling device), which

can be refluxed into the kettle or through a reflux curve The valve under the

head is recycled. After the reaction is completed, the materials can be

discharged from the side discharge port at the bottom of the kettle.This series

of products could be used with the vacuum equipment, high temperature or low

temperature circulation equipment, etc. to form a system device.

Basic configuration

1. The parts in contact with

materials are all made of high borosilicate glass (expansion coefficient 3.3)

and polytetrafluoroethylene materials, which are stable in performance and not

easy to chemically react with materials.

2. The bottom plate type main body

is made of aluminum alloy + stainless steel.

3. Glass + PTFE valve, No dead ends in the valve.

4. Electronic stepless speed

regulation, fine-tuning through the knob, the speed can be displayed digitally.

5. The mixing system adopts double

bearings and double skeleton oil seals.

6. The vacuum pressure display gauge.

7. Anchored stirring paddle, made

of 304 stainless steel, wrapped with PTFE tube, and the stirring blade is made

of PTFE.

Parameters

If you need any Customized laboratory glassware or the instrument,

Please contact with us

Be Made From G3.3 Borosilicate Glass

Annealing Point ------560℃

Linear Coefficient of Expansion------ 32×10-7/℃

Softening Point------820℃

- Stock: In Stock

- Model: 1063-1012-00